Raoul, wherever he is right now, is obviously a very bright person. I have promised myself to make the beautiful round wedges Raoul (conceptually) invented using a 3D printer one day. Here’s our exchange from the forum a few years ago:

Here you are: Print two of these, stack together and rotate until you get the correct angle (0-20 in this example). The image is not to scale, and it would benefit from some form of interlocking teeth between the two discs, but you get the idea…

RaoulDuke (May 28, 2017#11)

Still, there would be a problem with the bolts, right? They would need to be driven into channels with different directions, no? I mean, the first cylinder-slice-thing, once rotated by some angle clockwise, would have its holes facing in a direction slightly off the second cylinder-slice-thing’s holes, after you rotate that an equal angle counterclockwise. [isn’t that what you had in mind?]

(Alex)

I dont think so, if the holes are perpendicular to the surface between the two halves. The tricky part might be finding a hole pattern that allows for as many different angles as possible. I should print a pair to play around with…

Oh, right, yes, the holes will indeed meet each other aligned. But then when you set the slices to get an angle in between 0 and 20, the holes will not be on a plane parallel to the direction of the board (or some terminology like that) and the truck will be mounted slightly off the center of the deck. Right? [but even if it is so, it shouldn’t be too far to notice]

That is true, and the bolts would also be slanted to the left or right. I think a stack of several wedges might be easier to work with. If you split them along the center and cut slots instead of holes for the screws, you could even change angles without completely removing the screws.

You mean individual wedges, or? That was too hard for me to get…

You may try this if you have a 3d printer and please then show it to us. As these printers become more accessible, ideas like this will become invaluable. And also protect it somehow (a creative commons license or something), if only for recognition 😉

I mean this:

These could be slid under the baseplate without removing the screws, and they cannot slide out when the bolts are tight.

RaoulDuke (May 30, 2017#17)

I read about the existence of these things in a paper. I’ve never seen any mention of them in forums etc. I don’t know why, I think they are a fantastic idea. You hook your feet in there and you jump over curbs with your skateboard without having to learn how to do an ollie. This shop in Switzerland sells the ones depicted here, made by some brand called “Viking” and I’ve promised myself to get/make myself a pair one day.

While strictly speaking not a new idea, this youtuber nailed the 3D modeling of the skateboard. Here’s a fascinating short video of it.

A few years ago, a hobbyist with the online handle “Holden” figured out that spherical bearings are not meant to be used by professional truck makers, but only by DIY hobbyists without other means, who want a more precise hanger rotation. Exemplary of this is Dont Trip. In my view, Dont Trip was just mindlessly imitating forum users when it launched its Poppys. But if a professional truck maker is building a truck from the bottom up, then that maker might as well use a proper ball bearing, like every bearing on bicycles. And that’s what Holden did. Spherical bearings are meant for cases when the axis of rotation varies. A skateboard truck has a single, defined axis.

Holden also wanted to get rid of polyurethane bushings for the return-to-center force and use the far superior, in energy conservation and longevity terms, steel springs instead. Seismic does that, but its implementation is burdened by friction in every joint. Again, small ball bearings are needed.

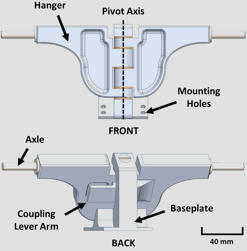

He came up with the trucks you cann see in the photo. Check out his blog for more details and my post on his plan to build a one-spring truck.

Suspension trucks done right? This bachelor student’s design seems to me at least more elaborate than the sloppy, all-over-the-place Avenue suspension trucks. The student’s idea promises a truck which is both compliant (i.e., has suspension) and precise.